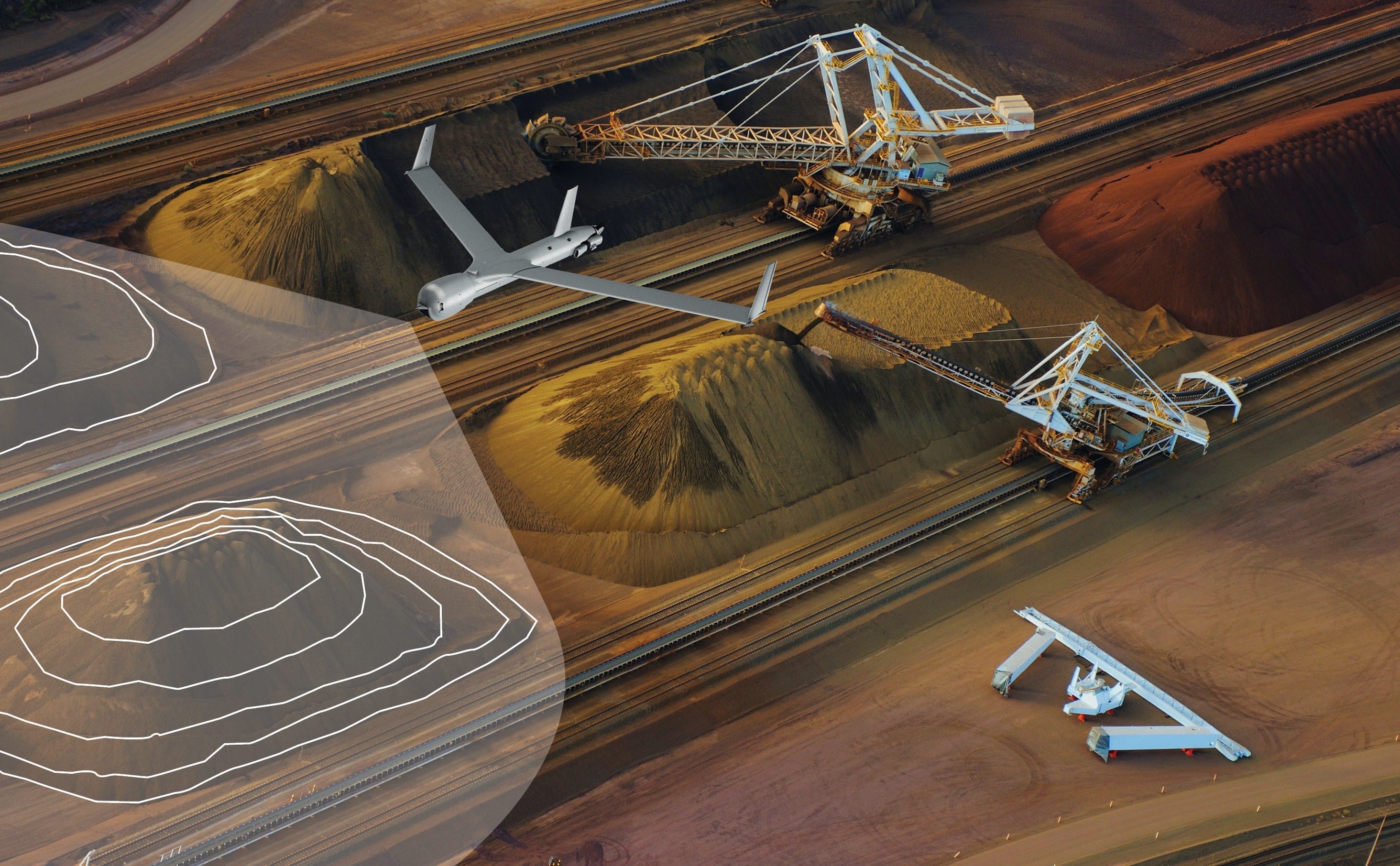

Optimise mine operations with aerial sensing

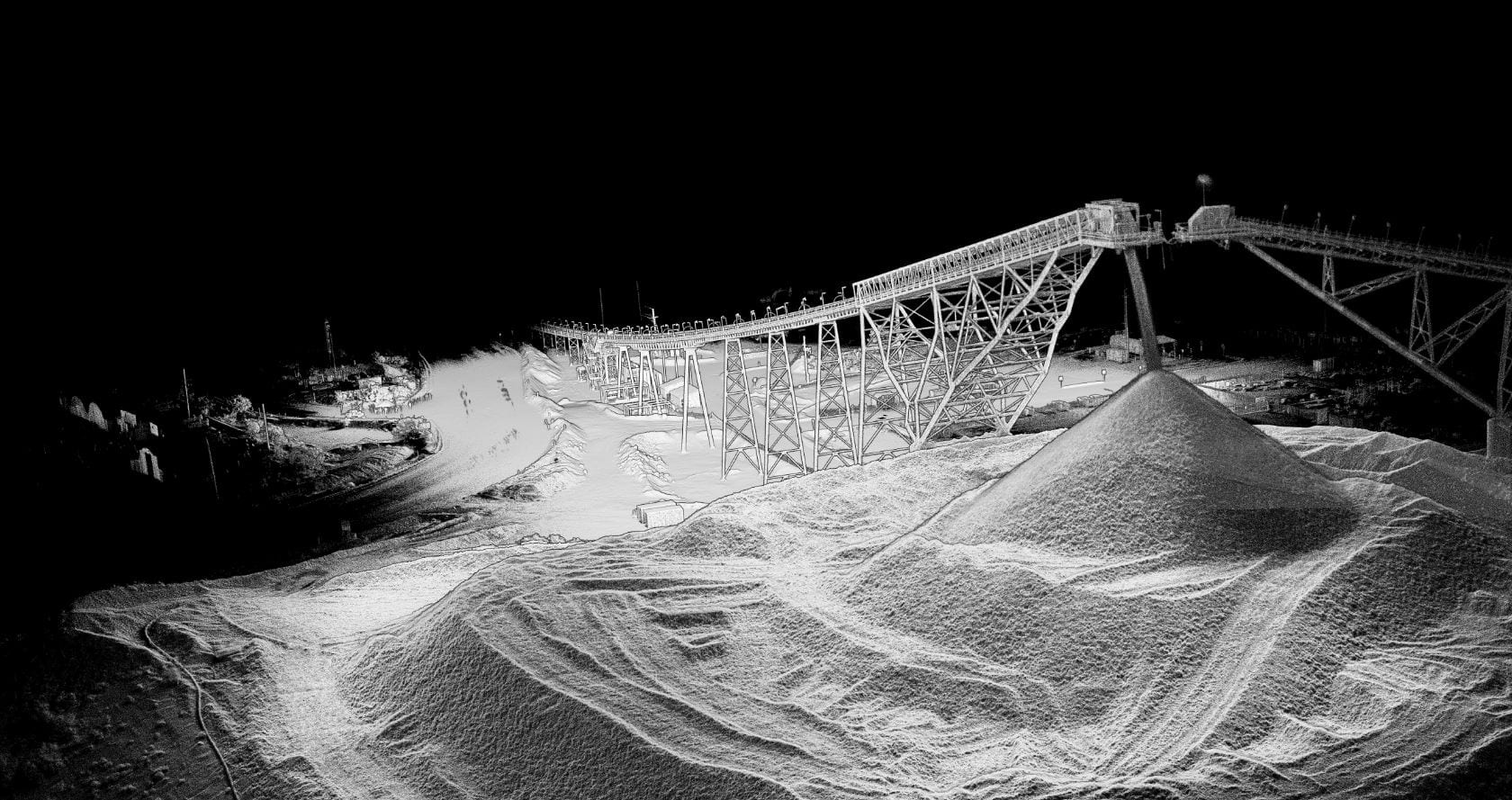

We deliver advanced UAS sensors and innovative data analysis underpinned by our leading aviation experience to optimise your operations — not only for active pits but across your entire mining, transport and shipping operation.

Achieve improved prospecting and exploration mapping, mineral recovery, minimise shutdowns, reduce human exposure to hazards, and increase production efficiencies via our INEXA Solutions information products featuring automated analytics.

![Insitu Pacific - [Page Template] - Footer](https://insitupacific.com.au/wp-content/uploads/insitu-map-test-01.png)